Catalyst manufacturing is a critical process for industries that rely on catalysts to facilitate certain processes. Some of the industries that depend on catalysts include:

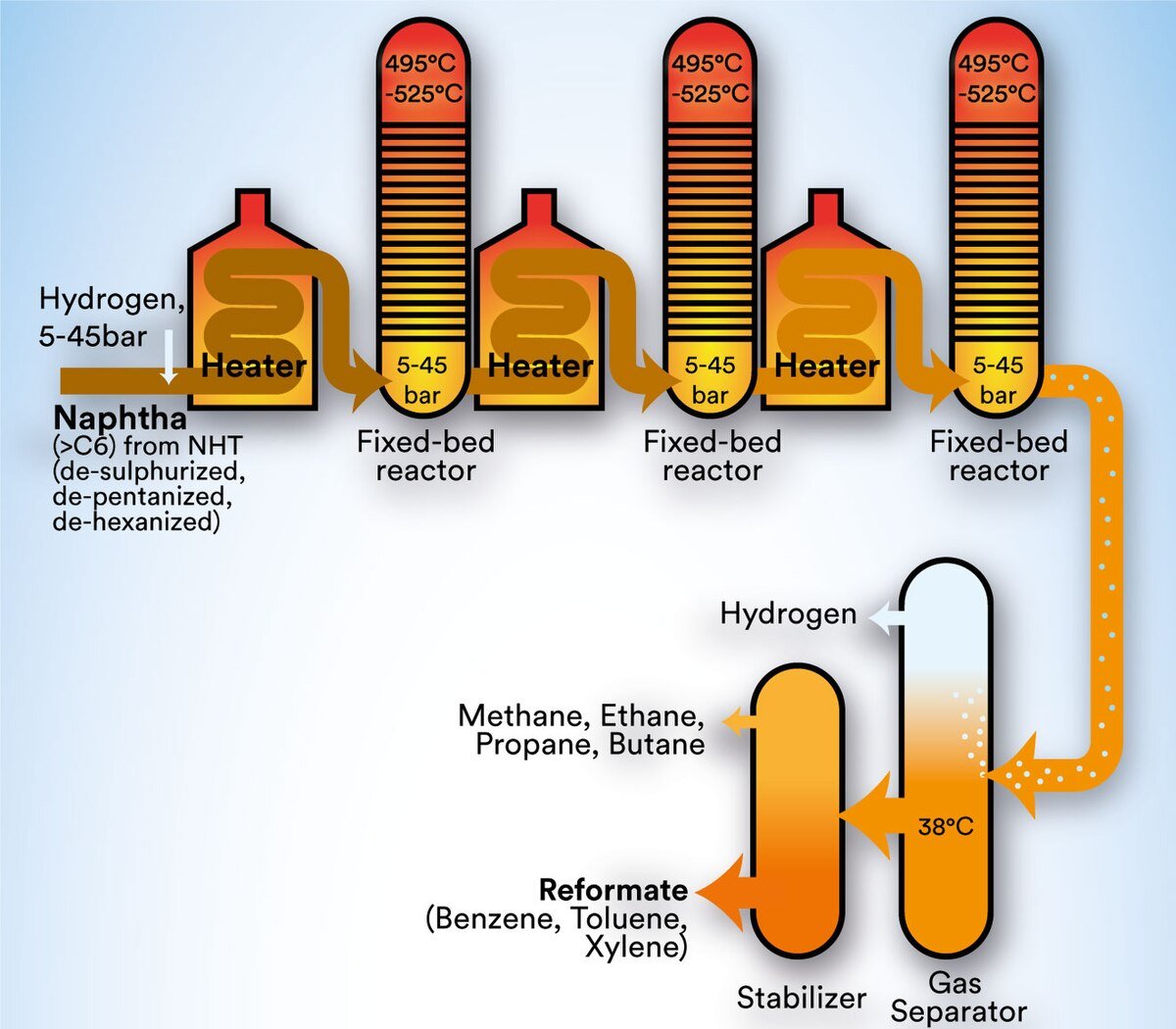

- Petroleum industries

- Auto industry

- Manufacturing industry (ex. polymer manufacturing)

- Industrial air pollution control

- And others

In truth, catalysts are actively applied in the production of more than 80% of manufactured products, which shows how important they are.

What is catalyst manufacturing?

Catalyst manufacturing is the process of designing, creating, testing and validating catalytic solutions. This process has a major impact on the qualities of catalysts such as performance, safety, environmental impact, efficiency, and more.

If you need catalytic products, you are supposed to engage leading catalyst manufacturing companies like Applied Catalysts for all your solutions so that you can get the best quality guarantee and peace of mind even if you are in a highly regulated industry.

Why does catalyst manufacturing matter?

Catalyst manufacturing is essential because of the following reasons:

1. It promotes efficiency in reactions

Since catalysts are supposed to boost the rate of chemical reactions without getting consumed by the reactions, they reduce the energy and resources needed in such processes. If, for example, a chemical reaction needs a certain quantity of chemical product, you will need less of that, while getting better efficiency scores for the processes.

2. Facilitates the creation of new products

Catalyst manufacturing makes it possible to come up with new products and materials, opening up new opportunities and markets that would, otherwise, be inactive. A good example is the use of catalysts in the production of polymers, which are used for a wide variety of products, including electronics and clothes.

3. Reduces environmental impact

Catalysts are instrumental in the reduction of harmful emissions into the environment during manufacturing processes in various ways. One is the reduction of the amounts of environmentally-harmful products used in manufacturing.

Another way is the breaking down of harmful emissions into their less harmful components, such as carbon monoxide being oxidized to carbon dioxide which is naturally present in the atmosphere.

4. Improves selectivity

Catalyst manufacturing makes it possible to have catalysts that promote selectivity in chemical reactions. Improved selectivity means that you can use certain chemical processes to create a specific product or byproduct with ease. This is especially common in the pharmaceutical industry where certain drugs such as anti-cancer drugs have to possess specific levels of selectivity.

5. Enhances product quality

Catalyst manufacturing facilitates the production of catalysts that can be used to enhance the quality of products. A good example is where catalysts are involved in producing food additives.

With efficient and reliable processes, the quality of additives will be higher, resulting in a higher overall quality of the product.

6. Increases safety during production

Some production processes can be quite unstable, thus requiring the use of a mechanism that reduces the amount of energy and resources required to achieve a certain result. Catalysts work perfectly to achieve this goal, ensuring the stability of specific chemical processes that would otherwise be untamable.

To sum it all up,

Catalyst manufacturing is a crucial input to modern manufacturing procedures and other processes such as environmental remediation, guaranteeing top-notch results.

Contact Applied Catalysts for all your standard and bespoke catalytic solutions and enjoy exceptional results. Keep reading such informative content at bhtnews.com