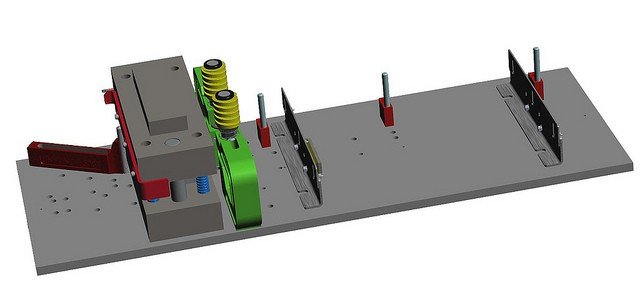

Cutting, bending, and shaping thin metal sheets into a final shape is known as sheet metal fabrication. One of the most common tools used in sheet metal fabrication is the punch and die set. A punch and die set is a tool that allows you to create holes, shapes, and contours in sheet metal by punching out pieces of the material using a combination of a punch and a die. In this blog post, we will explore the various aspects of sheet metal punch and die sets and how they are used in sheet metal fabrication.

What is a Punch and Die Set?

A punch and die set consists of two main components: a punch and a die. The punch is a metal rod with a flat or pointed end that is used to make a hole in the sheet metal. The die is a metal plate with a hole that matches the size and shape of the punch. The punch is inserted into the die and then the sheet metal is placed on top of the die. The punch is then pressed down onto the sheet metal, causing it to punch through the hole in the die and create a hole in the sheet metal.

Types of Punch and Die Sets

There are several types of sheet metal punch and die sets that are used in sheet metal fabrication. The most common types include:

- Round Punch and Die Set: This type of punch and die set is used to create round holes in sheet metal. It is the most basic type of punch and die set and is used for a wide range of applications.

- Square Punch and Die Set: This type of punch and die set is used to create square holes in sheet metal. It is commonly used for creating openings for switches and electrical outlets.

- Oblong Punch and Die Set: This type of punch and die set is used to create oblong or rectangular holes in sheet metal. It is commonly used for creating openings for vents and louvers.

- Notching Punch and Die Set: This type of punch and die set is used to create notches in sheet metal. It is commonly used for creating tabs and slots for joining two pieces of sheet metal together.

Choosing the Right Punch and Die Set

When choosing a punch and die set, there are several factors to consider. These include the size of the hole or shape that you need to create, the thickness of the sheet metal that you will be working with, and the type of material that you will be punching. It is important to choose the right punch and die set for the job to ensure that you get clean, accurate results.

Using a Punch and Die Set

Using a punch and die set requires proper technique to ensure that you get clean, accurate results. Here are some tips for using a sheet metal punch and die set:

- Choose the appropriate punch and die set for the job.

- Secure the sheet metal in place on the die using clamps or other methods.

- Position the punch over the desired location for the hole or shape.

- Use a hammer or press to apply force to the punch, causing it to punch through the sheet metal and into the die.

- Remove the sheet metal from the die and repeat the process as needed.

Here are some tips for using a punch and die set:

- For eye protection against flying debris, always use safety glasses.

- Use a flat, stable surface to support the sheet metal and die.

- Make sure that the punch and die are properly aligned before punching.

- Apply even pressure to the punch to avoid warping or bending the sheet metal.

- Use lubricant to help reduce friction and prevent the punch and die from becoming damaged.

Maintenance and Care

To ensure that your punch and die set lasts for as long as possible and continues to provide accurate results, it is important to take proper care of it. This includes keeping the punch and die set clean and free of debris, regularly lubricating the punch and die with oil or grease, and storing the punch and die set in a dry, cool place when not in use.

- Clean the punch and die after each use to remove debris and prevent rust.

- Lubricate the punch and die with oil or grease to prevent rust and reduce friction.

- Store the punch and die set in a dry, cool, and clean place to prevent rust and other damage.

- Inspect the punch and die set regularly for signs of wear and damage. Replace any worn or damaged parts as necessary to ensure accurate results and prevent further damage.

- Follow the manufacturer’s instructions for sharpening and maintaining the punch and die set. Improper sharpening can damage the tool and affect its accuracy.

Punch and die sets are versatile and essential tools for sheet metal fabrication. With various types and sizes available, it’s important to choose the right sheet metal punch and die set for your specific application. Proper technique and maintenance will ensure that your punch and die set provides accurate results for many years.

Conclusion

Punch and die sets are essential tools for sheet metal fabrication. They allow you to create precise holes, shapes, and contours in sheet metal quickly and easily. By understanding the different types of punch and die sets, how to choose the right one for the job, and proper maintenance and care, you can ensure that your punch and die set will last for many years and continue to provide accurate results. Whether you are a professional sheet metal fabricator or a DIY enthusiast, a punch and die set is a tool that you will want to have in your toolbox. By following the guidelines outlined in this blog post, you can make the most out of your punch and die set and create high-quality sheet metal products. So go ahead and give it a try!