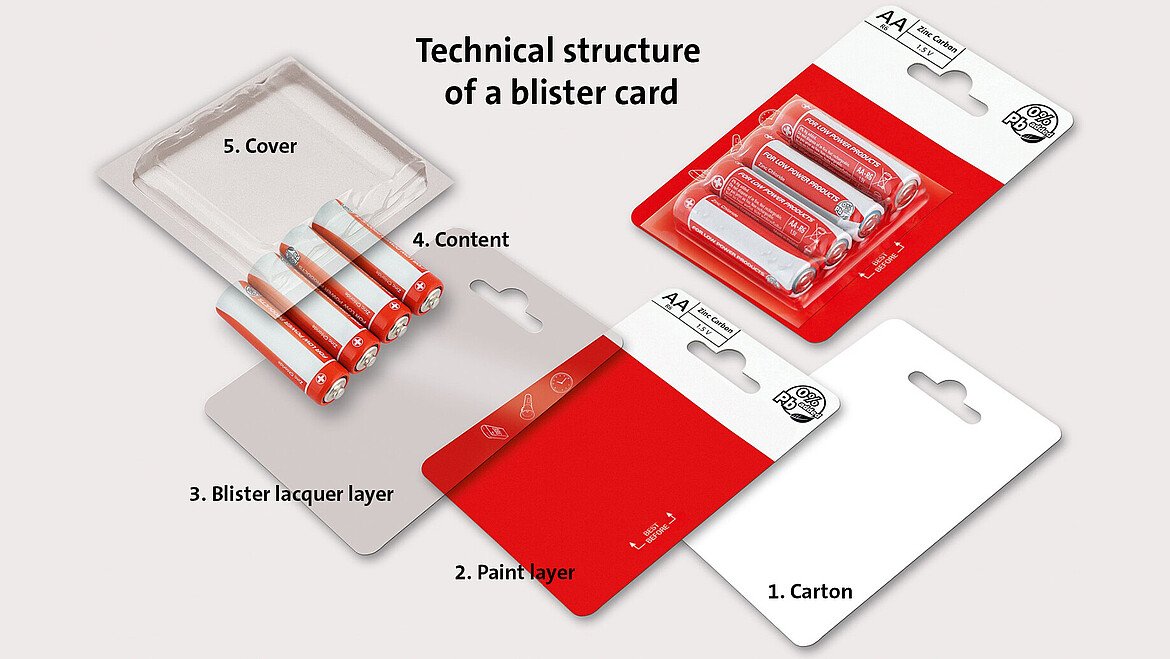

Blister Cards are a popular form of packaging that is used to protect and display a variety of different products. They are typically made from clear plastic and have a small cavity that is designed to hold the product securely in place. Blister Cards are used in a variety of industries, including the pharmaceutical, electronics, and toy industries, and are an effective way to ensure that products are protected during shipping and handling.

Blister Card Packaging is a process of enclosing products in blister cards to protect them during transportation and storage. Blister card packaging is used in a variety of industries, from retail to pharmaceuticals, where products need to be protected from damage, contamination, and tampering. The packaging is designed to be tamper-proof, ensuring that the product inside remains safe and secure until it reaches the customer.

Blister Card Printing is the process of printing the artwork, branding, and other information onto blister cards. The printing process involves using a printing press to transfer ink onto the surface of the blister card. The artwork can be customized to meet the needs of the customer, including adding logos, product names, and other branding elements.

A custom Blister Card is a type of blister card that is made to fit the specific needs of the customer. The card can be customized in terms of size, shape, and material to meet the requirements of the product being packaged. Custom blister cards are an effective way to ensure that products are packaged in a way that is both functional and aesthetically pleasing.

Advantages of Blister Cards:

- Protection: Blister cards offer excellent protection for products, keeping them safe from damage during shipping and handling. Clear plastic allows customers to see the product without having to open the packaging, reducing the risk of damage or contamination.

- Display: Blister cards are an effective way to display products, allowing customers to see the product before purchasing. The clear plastic packaging also makes it easy to identify the product on store shelves.

- Tamper-proof: Blister cards are designed to be tamper-proof, making it difficult for anyone to access the product inside without damaging the packaging. This ensures that the product remains safe and secure until it reaches the customer.

- Customizable: Blister cards can be customized to meet the specific needs of the customer, including size, shape, and material. This makes them an effective way to package a wide range of products.

- Cost-effective: Blister cards are a cost-effective way to package products, reducing the need for expensive packaging materials and reducing shipping costs.

Blister Card Packaging:

Blister Card Packaging is an effective way to protect products during shipping and handling. The packaging is designed to be tamper-proof, ensuring that the product remains safe and secure until it reaches the customer. Blister card packaging is used in a variety of industries, including the pharmaceutical, electronics, and toy industries, and is an effective way to protect products from damage, contamination, and tampering.

Blister Card Packaging is typically made from clear plastic, which allows customers to see the product without having to open the packaging. The packaging is designed to hold the product securely in place, reducing the risk of damage during shipping and handling. The clear plastic also makes it easy to identify the product on store shelves, making it an effective way to display products.

Blister Card Packaging can be customized to meet the needs of the customer, including adding branding elements, product names, and other information. The packaging can also be customized in terms of size and shape, making it an effective way to package a wide range of products.

Blister Card Printing:

Blister Card Printing is the process of printing the artwork, branding, and other information onto blister cards. The printing process involves using a printing press to transfer ink onto the surface of the blister card.

Blister Card Printing is a crucial step in the packaging process that adds visual appeal and informative elements to the blister cards. The printing process involves the use of advanced printing techniques and equipment to transfer ink onto the surface of the blister cards.

There are several key aspects to consider when it comes to Blister Card Printing:

- Customization: Blister Card Printing allows for customization options to meet the specific needs of the product and brand. This includes incorporating brand logos, product names, descriptions, barcodes, and other essential information. The flexibility in design and customization helps to create a visually appealing and informative packaging solution.

- High-Quality Printing: The quality of the printing plays a crucial role in the overall presentation of the product. Blister Card Printing utilizes advanced printing technologies, such as offset printing or digital printing, to achieve sharp, vibrant, and accurate printing results. The use of high-quality inks ensures that the artwork and text on the blister cards are crisp and durable.

- Branding Opportunities: Blister Card Printing offers excellent branding opportunities by allowing companies to showcase their brand identity. Customized blister cards with brand logos and consistent color schemes help to reinforce brand recognition and create a professional image in the market. It enables customers to associate the product with the brand, enhancing brand loyalty and trust.

- Product Information and Graphics: Blister Card Printing enables the inclusion of important product information, such as instructions for use, ingredients, warnings, and benefits. Additionally, it allows the integration of eye-catching graphics, product images, or illustrations to visually communicate the product features and appeal to the target audience. Clear and concise information helps consumers make informed purchasing decisions.

- Compliance with Regulations: Blister Card Printing ensures compliance with regulatory requirements, such as labeling guidelines and safety information. This is particularly important for industries like pharmaceuticals, where accurate and compliant labeling is essential. Proper printing techniques and materials are used to meet industry standards and ensure that all necessary information is displayed on the blister cards.

- Enhancing Shelf Appeal: Well-executed Blister Card Printing can significantly enhance the shelf appeal of the product. Eye-catching designs, vibrant colors, and attractive visuals help the product stand out among competitors on store shelves. Packaging becomes an effective marketing tool that captures the attention of potential customers and entices them to make a purchase.

In conclusion,

Blister Card Printing is an essential aspect of the packaging process that adds visual appeal, branding elements, and informative details to the blister cards. It offers customization options, high-quality printing results, branding opportunities, and compliance with regulations. Blister Card Printing enhances the overall presentation of the product, communicates essential information to consumers, and helps the product gain shelf appeal. By utilizing advanced printing techniques and materials, companies can create impactful and attractive blister cards that leave a lasting impression on customers.